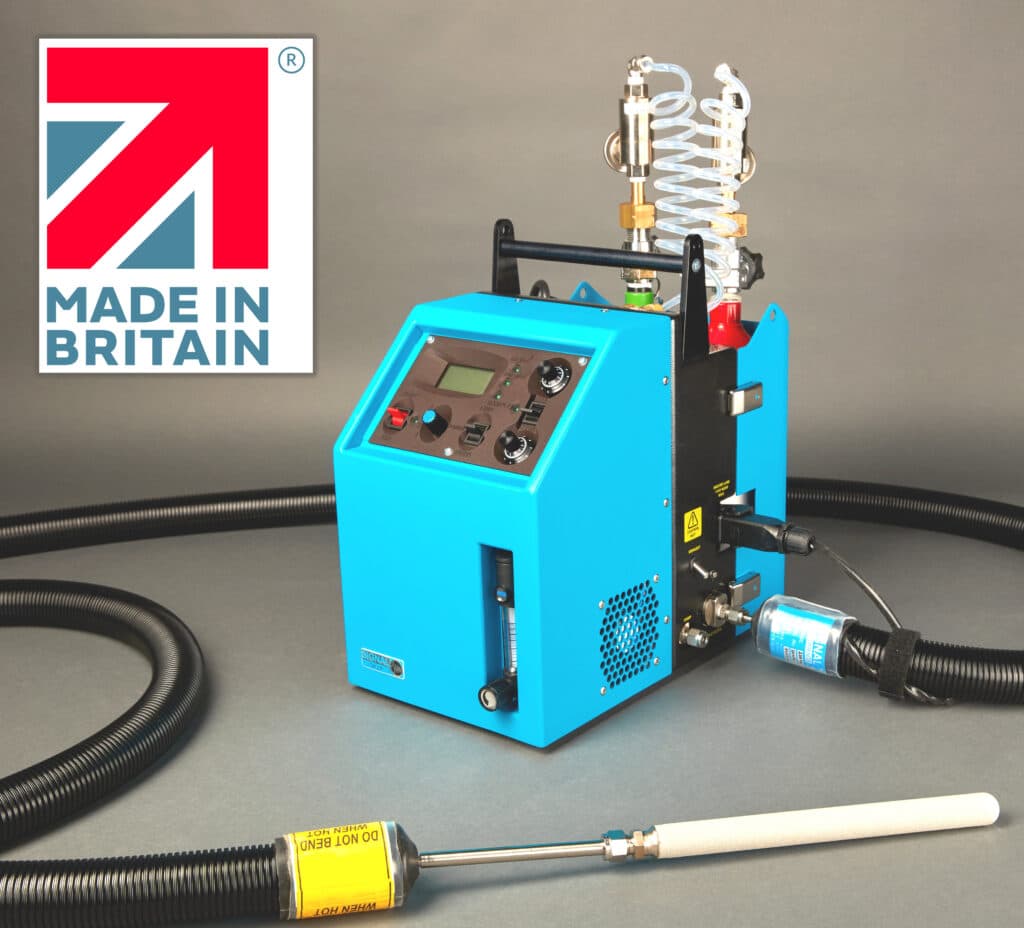

The 320 Cutter provides a low cost alternative to “all in one” FIDs with a built in cutter. Housed in a portable case suitable for inline usage with portable and fixed equipment, this unit is ideal for use with the 3010 MINIFID. Two modes of operation allow a reading for either total hydrocarbons or methane only, allowing you to read a value for non-methane hydrocarbon concentration. In the methane mode the sample is directed through a heated catalyst.

This catalyst oxidises non-methane species of hydrocarbons in the sample. The THC mode bypasses this catalyst to provide a reading for total hydrocarbon. These two modes allow the der4ation of a non-methane hydrocarbon by simply deducting the methane only reading from the total hydrocarbon value. As a stand alone unit, this cutter is suitable for use with any heated FID to obtain a methane only or non-methane concentration reading.