Signal Group’s sample handling modules and components condition gas samples in preparation for analysis. 1/8”, ¼”, 3/8” and ½” versions, and their metric equivalents (3mm, 6mm, 10mm, 13mm). 1m to 50m in length. Signal Group’s Trace heated line is designed to convey hot exhaust gasses from sample points and probes to analyser, without compromising sample integrity. With safety a major consideration the tough, flexible line is electrically isolated from the main supply and is thermally insulated to allow handling even at full temperature.

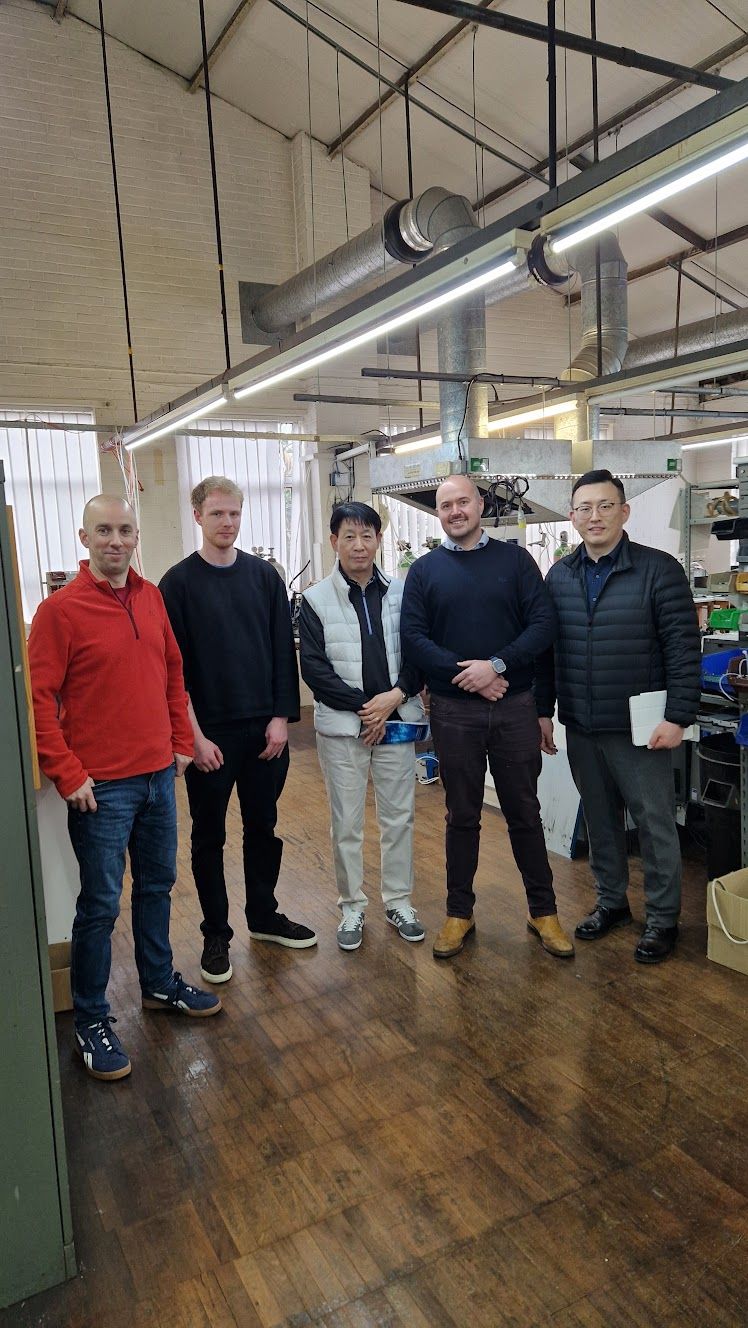

Signal partners with gas analysis experts in Korea

Signal Group has announced the further expansion of its network of international distributors with the appointment of Y&J Eng in South Korea. “Asia is fast