Global regulations limit the environmental emissions of volatile organic compounds (VOCs) from industrial processes. This is because VOCs contribute to the formation of ozone, a constituent of photochemical smog. Methane and some halogenated VOCs, such as refrigerants, are also powerful greenhouse gases, and thereby contribute to climate change. Also, in high concentrations, many VOCs are flammable and explosive. Accurate VOC emissions monitoring is therefore necessary to protect the environment and ensure compliance with environmental permits.

Workplace safety regulations limit the exposure of workers to volatile organic compounds (VOCs) from solvents, fuels, petrochemicals, paints, adhesives, cleaning products etc. Some VOCs are harmful to the skin or eyes, and can be absorbed, but their volatility means that they can be inhaled, and may cause a wide variety of negative health effects ranging from minor irritation to cancer, and even death.

VOCs can be released into the environment by leaks and fugitive emissions, and from both evaporative and combustion emissions from industrial processes, particularly where combustion involves the use of an organic fuel. This includes fossil fuels such as petrol, diesel and oil, as well as the incineration of wastes and biofuels.

By monitoring total organic carbon (TOC) concentration in emissions, process operators can demonstrate compliance with relevant legislation, as well as provide insights for process optimization, because the presence of organic compounds is an indicator of incomplete combustion. In addition, it is common practice to monitor TOC in order to measure the effectiveness of abatement processes.

Transportable Continuous Emission Monitoring Systems (T-CEMs) are generally employed for regulatory monitoring; verifying and calibrating installed CEMs, and for providing temporary back-up when permanent CEMs are not operating.

With over 40 years of experience in designing VOC analysers, Signal Group has specialised in developing instruments that enable process operators to demonstrate compliance. The company’s monitoring solutions include both fixed and portable VOC analyzers. However, as Managing Director James Clements explains: “Accurate measurements rely on more than just a reliable, accurate analyzer. It is also necessary for the instrument to be calibrated correctly, and for a representative sample to be delivered to the analyzer. We have therefore also developed a range of the ancillary equipment that is essential to achieving that goal. This includes gas dividers, methane cutters, gas filters, heated sample lines, sample probes and cooler/dryers.”

In most countries, the emissions of regulated processes with the potential to release VOCs are issued with permits that include an emission limit for total organic carbon (TOC). The Standard Reference Method for the measurement of TOC is with a Flame Ionisation Detector (FID). In some cases, it may be necessary for the monitoring activity to speciate toxic VOCs or to distinguish between methane and non-methane VOCs.

VOC monitoring, both continuous and periodic, plays a key role in demonstrating compliance. However, Signal’s customers also use FIDs to measure the effects of mitigation measures; to check the performance of abatement equipment; for process control, and to investigate diffuse emissions.

Reducing VOC emissions in the USA

In the United States, the Clean Air Act is a federal law regulating air emissions from stationary and mobile sources. The Act authorises the United States Environmental Protection Agency (US EPA) to establish National Ambient Air Quality Standards (NAAQS) to protect public health and to regulate the emissions of hazardous air pollutants. The EPA has therefore published a list of hazardous air pollutants, many of which are VOCs.

VOCs can contribute to non-attainment with the NAAQS or may adversely affect the attainment status of an area. The EPA has addressed serious violations through enforcement actions, achieving measurable pollutant reductions and improving air quality. Through partnerships with state and tribal authorities, the US EPA has conducted multiple joint inspections and joint enforcement actions, and this has resulted in a significant reduction of VOC emissions, particularly from the oil & gas sector.

In the USA, Method 25 is applicable for the determination of VOCs (measured as total gaseous non-methane organics (TGNMO) and reported as carbon) in stationary source emissions. The Method says: “Direct measurement of an effluent with a flame ionization detector (FID) analyzer may be appropriate with prior characterization of the gas stream and knowledge that the detector responds predictably to the organic compounds in the stream. If present, methane (CH4) will, of course, also be measured.

The FID can be used under any of the following limited conditions:

- Where only one compound is known to exist;

- When the organic compounds consist of only hydrogen and carbon;

- Where the relative percentages of the compounds are known or can be determined, and the FID responses to the compounds are known;

- Where a consistent mixture of the compounds exists before and after emission control and only the relative concentrations are to be assessed; or

- Where the FID can be calibrated against mass standards of the compounds emitted (solvent emissions, for example).

Another example of the use of a direct FID is as a screening method. If there is enough information available to provide a rough estimate of the analyzer accuracy, the FID analyzer can be used to determine the VOC content of an uncharacterized gas stream. With a sufficient buffer to account for possible inaccuracies, the direct FID can be a useful tool to obtain the desired results without costly exact determination.”

Alternatively, Method 25A applies to the determination of total gaseous organic concentration of vapours consisting primarily of alkanes, alkenes, and/or aromatic hydrocarbons. The concentration is expressed in terms of propane (or other appropriate organic calibration gas) or in terms of carbon. Again, the Method stipulates the collection of a heated gas sample which is passed to a flame ionization analyser.

VOC monitoring

Typically, the level of monitoring required by regulators is dictated by the scale of an operator’s VOC emissions, with continuous monitoring required for the larger emitters and discontinuous monitoring for processes with lower emissions. Signal Group has therefore developed VOC analyzers to meet both requirements – portable heated FIDs (Signal 3010 MINIFID and S4 SOLAR XPLORE) for periodic measurements and a continuous heated FID (S4 SOLAR) for permanent installations.

The continuous monitoring heated FID S4 SOLAR analyser can be easily fitted into a 19” rack cabinet for indoor or outdoor installation. The analyser has an embedded microprocessor which automatically starts the analyser upon receipt of a command from a detachable tablet, or from a remote installation with Signal’s S4i software. This command sets in place a sequence of analyser actions which prepare the analyser to take samples and report calibrated readings to the instrument’s internal datalogger.

Using an optional detachable tablet, users are able to manage the analyser wirelessly up to 50 metres away from the analyser. In addition, using the remote S4i software over an Ethernet connection, the analyser can be operated from anywhere at any time. This remote accessibility also means that the Signal after-sales team or one of Signal’s US Representatives can monitor alarms, conduct remote calibration and even troubleshoot if necessary.

Signal’s portable heated FIDs are suitable for a variety of applications:

- Compliance monitoring where the permit requires discontinuous measurements

- Calibration of CEMS

- Temporary back-up for CEMS

- Checking abatement performance

- Fugitive emissions investigations

- Process optimization

Signal 3010 MINIFID (portable)

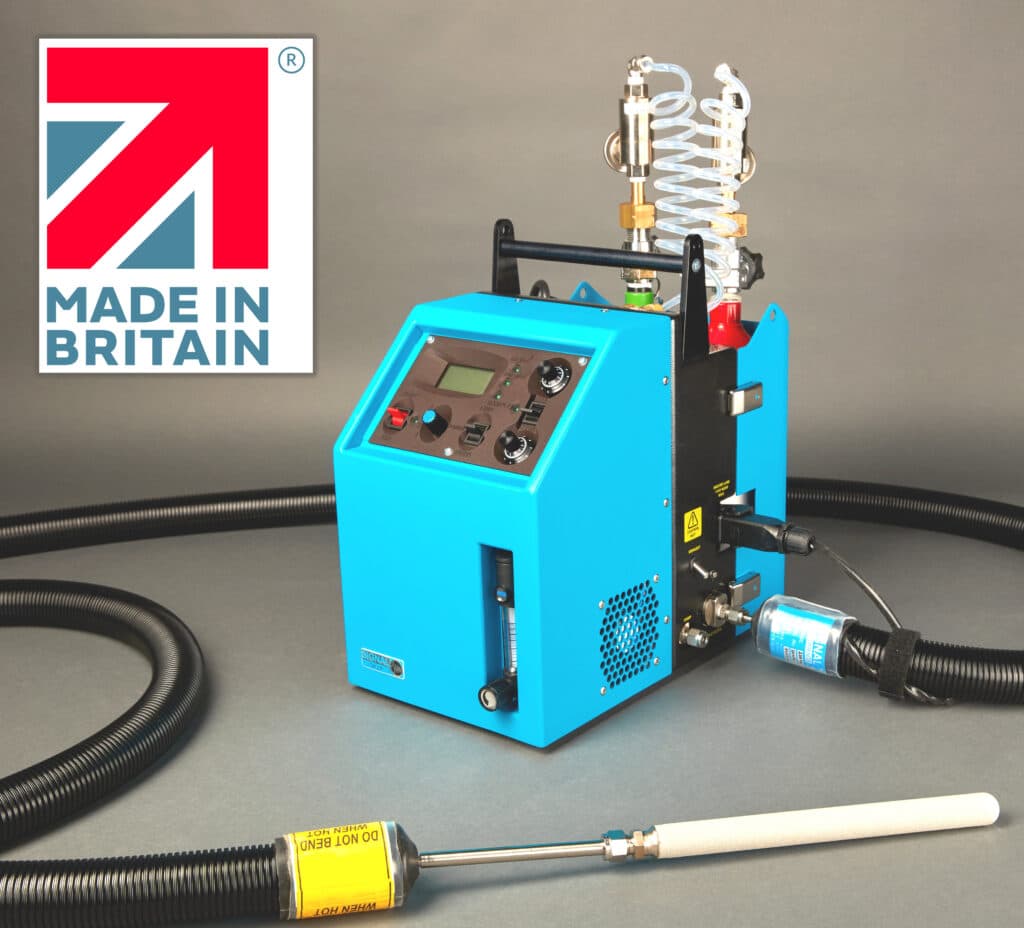

In contrast with most of the other ‘portable’ FIDs on the market, the 3010 MINIFID was designed as a rugged, portable field-use instrument. With an optional internal datalogger (and memory stick), sample pump, inlet filter, heated line controller and a detachable gas bottle holder, the 3010 MINIFID is compact and portable. The analyser’s detachable bottle holder accommodates both the burner gas and the calibration gas, with zero air provided with a background hydrocarbons purifier.

The instrument is simple to operate:

- Switch on, wait for the temperature interlock to reach set temperature.

- Turn gases on, press “Ignite” switch.

- Wait for the reading to settle, select “Zero” gas and adjust dial to read zero on the analyser display.

- Select “Span” and adjust span dial to read the value of the calibration gas.

- Select “Sample” and the analyser will start drawing sample gas through the heated line.

- Wait a few minutes for the sample gas to arrive at the analyser and the instrument will start to display readings, which may be logged to the memory stick for later examination and reporting.

Many 3010 MINIFID users are process operators, but a larger number are environmental consultants or test houses that provide monitoring services. This is because stack testers require instruments that are rugged, reliable and designed for field operation in multiple locations.

Signal S4 SOLAR XPLORE (portable)

As the most recent addition to Signal’s range of advanced FID analysers, the S4 SOLAR XPLORE is a compact, portable version of the fixed S4 SOLAR rack mounted analyser. The XPLORE therefore offers a broader range of features than the MINIFID. For example, the XPLORE has a detachable tablet with inbuilt 802.11 Wi-Fi, which means that the analyzer can be operated remotely up to 50 metres away. This provides users with the ability to view live data in a different location, and even manage datalogging, alarms and calibration from a distance. James Clements adds: “Typically, customers find the tablet most useful when it is necessary to install the analyser in a location with difficult access – such as: in vehicle exhaust gas test cells; in an ATEX enclosure; on a raised gantry on a stack; in a combustion test rig, or on any site where the location of analysis is not an ideal or safe working space.”

In addition to wireless connectivity between the analyser and the display, all Series IV instruments have their own IP address, and are compatible with cellular, Bluetooth, Wi-Fi and satellite communications. This provides users with simple and secure access to their analysers at any time, from anywhere.

The XPLORE can also be fitted with dual FID detectors for simultaneous monitoring of THC, NMHC and methane, so customers should specify this option when ordering.

Summary

FID analysers are ideal for a variety of VOC emissions monitoring applications – the list given in Method 25 provides a useful guide. It is important to remember that while Flame Ionisation is the reference method for the monitoring of VOCs, the response of the analyser will vary according to the VOC or VOCs present in the sample.

With many decades of experience in the development of FIDs, Signal Group is one of the only FID manufacturers in the world to continually develop its analysers. The company’s in-house experts are able to provide help and advice on which instruments and accessories are necessary, and on how to deliver high quality, reliable, defensible monitoring data. For more information, contact one of Signal’s USA representatives, or visit www.signal-group.com.